What are Level Transmitters?

Type, working principle and how to choose

Type, working principle and how to choose

Level transmitters are sensors used to measure and monitor the level of liquids or bulk solids in tanks, silos, river water, and tidal environments (sea level).

There are various types of level transmitters, each based on different measurement principles and featuring unique characteristics depending on the manufacturer.

Selecting the appropriate level transmitter requires careful consideration of key conditions such as the physical properties of the material, the measurement environment, installation conditions, and potential disturbances.

This article introduces the operating principles, features, and limitations of each measurement method.

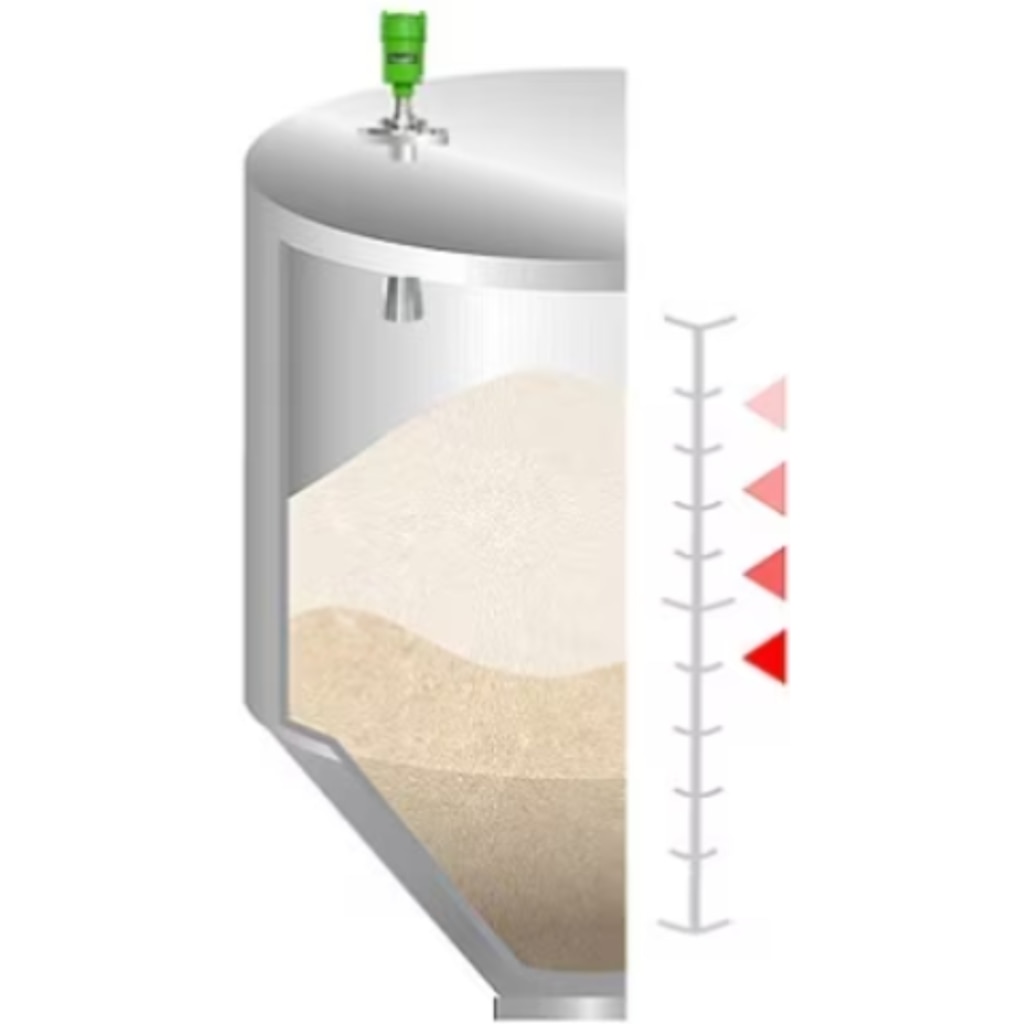

Level Transmitters are used in mass-producing factories, such as material industry, to measure amount stored in silos and tanks that store raw materials and products.

In factories, it is necessary to continuously send raw materials to next process so that production does not stop. Therefore, it is necessary to replenish raw materials before storage capacity in the silo runs out so that production can continue.

It would be extremely inefficient to monitor levels of each of these facilities individually, so level meters are used to monitor and automate (control) storage levels.

There are two main types of sensors for level measurement, "Level Transmitter" and "Level Switch".

The amount stored in container is continuously measured and displayed as ***%, level ***m, etc., and is used as an approximate storage level.

The measured value is converted from 0 to 100% into an instrumentation signal of 4 to 20 mA DC or 1 to 5 V and output, which is used for monitoring and control.

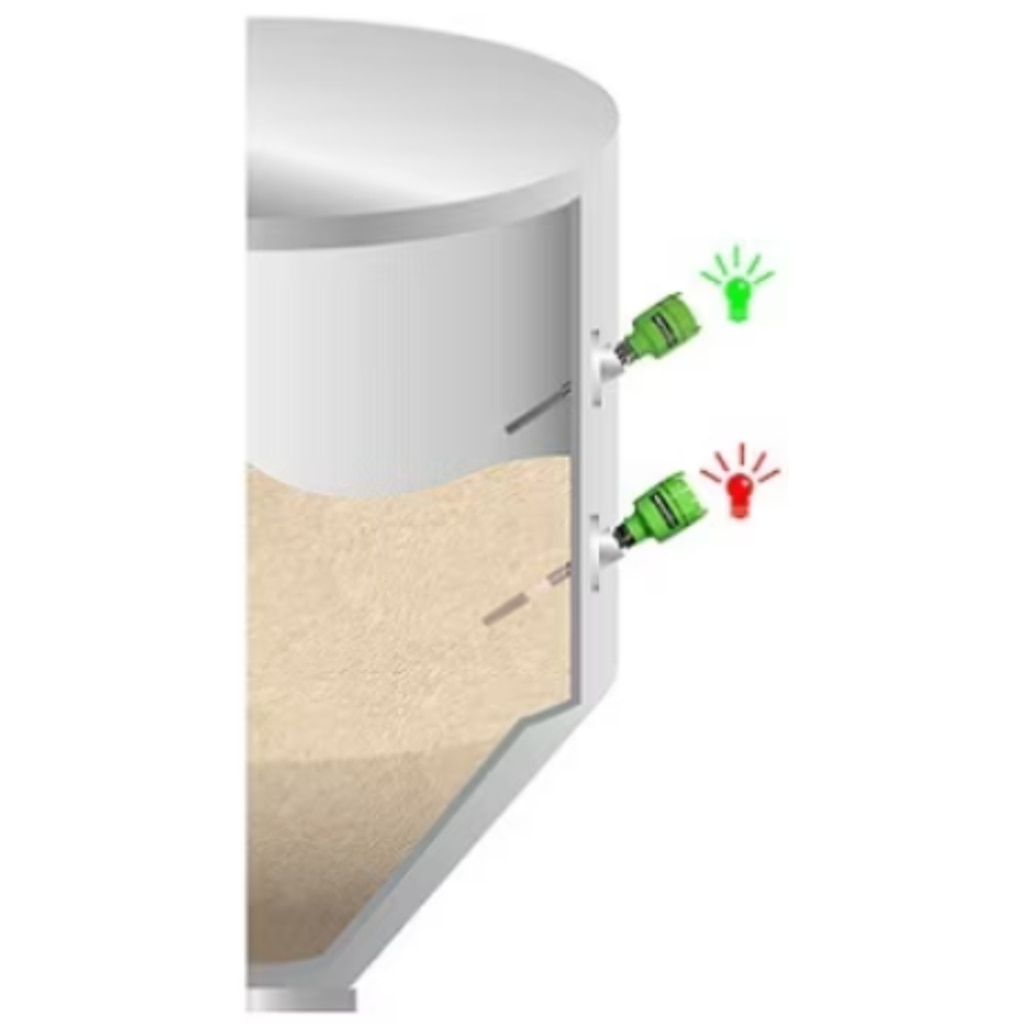

This is a switch designed to detect full or empty conditions by installing the sensor at a predetermined level inside a container.

It is commonly used to control the start and stop of material loading and unloading processes. When the preset level is reached, the switch outputs an ON/OFF contact signal.

Small containers are often controlled with just a Level Switch, but for medium-sized and large containers, instead of installing multiple Level Switches at the top, middle, and bottom, a Level Transmitter is used to continuously measure the storage level and calculate approximate storage level in real time.

It is often displayed and used.

In some cases, Level Transmitter is also used to check the intermediate storage amount while controlling with a Level Switch.

This also has the advantage of making it easier to notice if there is a problem with a certain sensor.

Since it can be detected early, it can reduce impact on production process and prevent stress on equipment.

There are many types of level meters and level switches depending on the object to be measured and the measurement environment.

Please check the measurement object and environment to be used and select the one that matches.

Also, not everything will match. In such cases, there are many cases where special specifications are available, so please contact the manufacturer in such cases.

Please refer to the information below that will help you select a model.

There are various types of level transmitters available on the market.

You may feel that you understand the characteristics of each type, yet find it difficult to decide which model to select when it comes to actual application.

To help with this, this article explains not only the types and features of level transmitters, but also their limitations.

Level transmitters vary in measurement principles and manufacturer-specific features. Selecting the appropriate device requires careful consideration of material properties, process conditions, installation requirements, and external disturbances.

Measurement methods can be broadly divided into distance-based and direct level measurement types.

This article explains the principles, features, and limitations of each method, focusing on powder, granular, and bulk material applications.

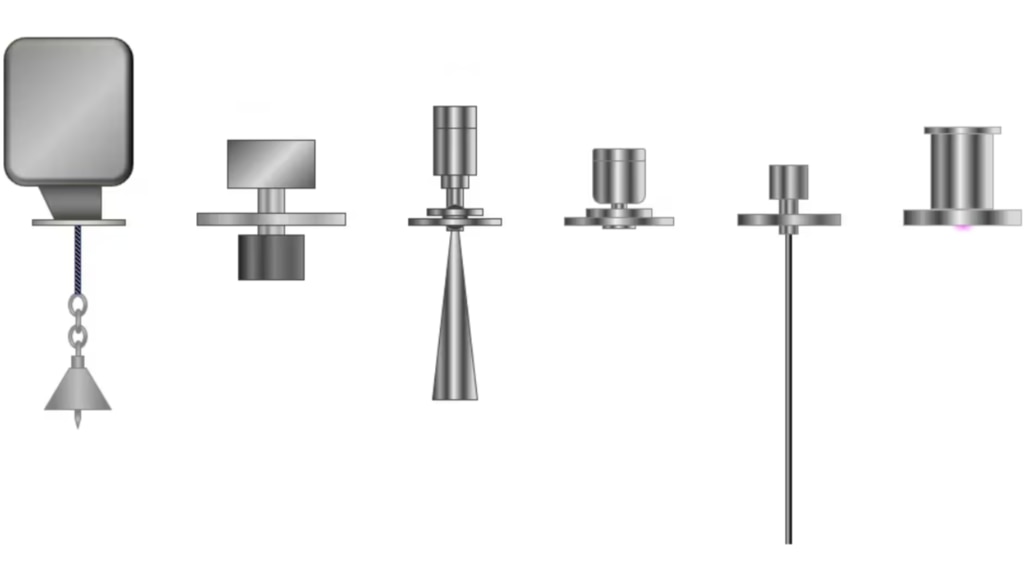

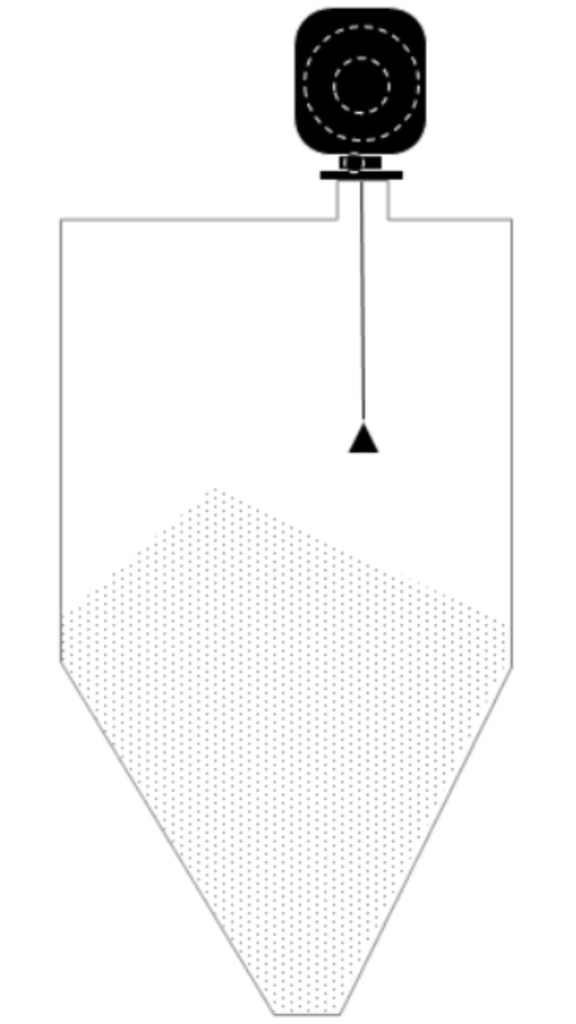

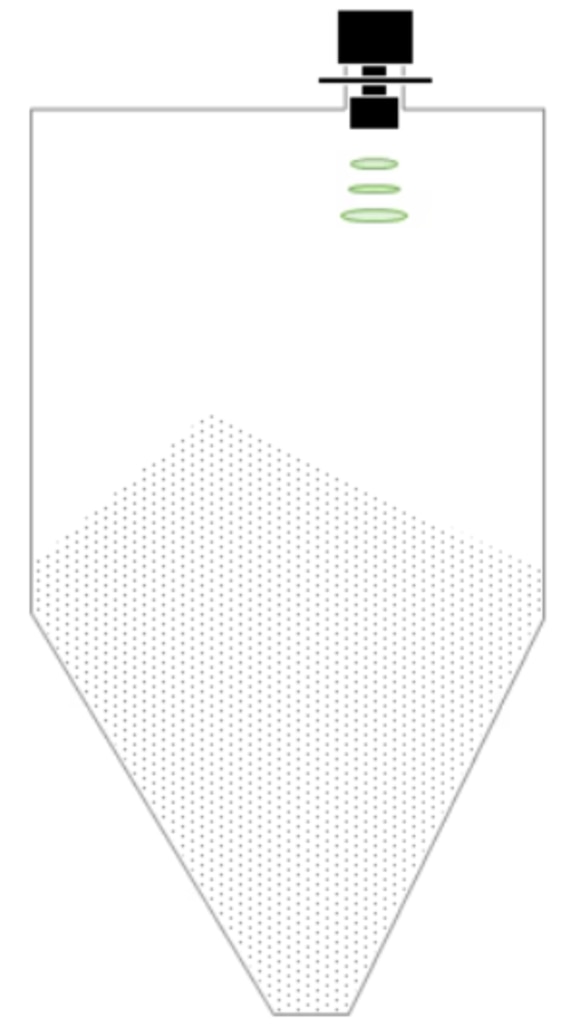

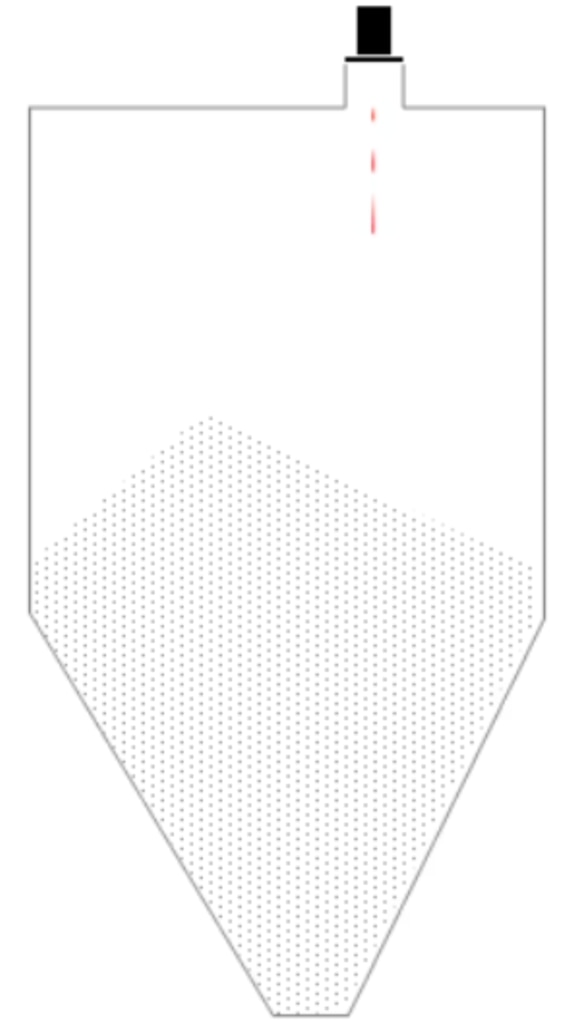

A sensing weight is electrically lowered by a motor until it contacts the material surface. The empty distance is calculated from the measured travel time and the lowering speed. (Distance = Speed x Time)

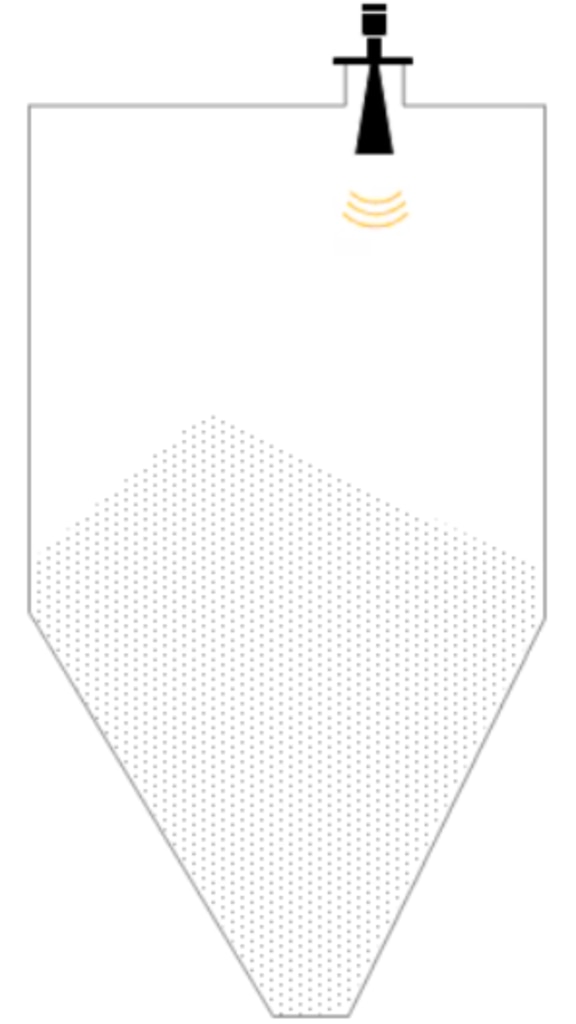

This is a non-contact level transmitter that measures the empty distance by transmitting an ultrasonic pulse toward the material surface and detecting the time required for the reflected signal to return to the sensor.

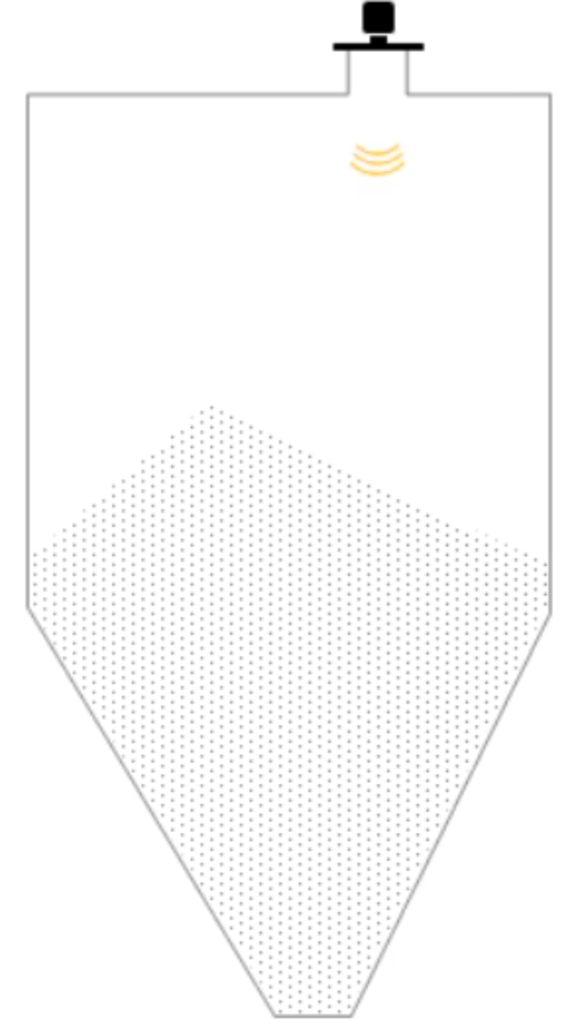

A radar level transmitter operates by emitting microwave pulses toward the material surface and calculating the empty distance based on the round-trip travel time of the reflected signals.

Materials with a low dielectric constant may not be detectable due to weak radar signal reflection.

Example: silica

A non-contact level meter based on FMCW radar technology. Frequency-modulated continuous microwaves are transmitted from the sensor, and the distance is determined by analyzing the frequency difference between the transmitted signal and the signal reflected from the material surface.

Materials with a low dielectric constant may not be detectable due to weak radar signal reflection.

Example: silica

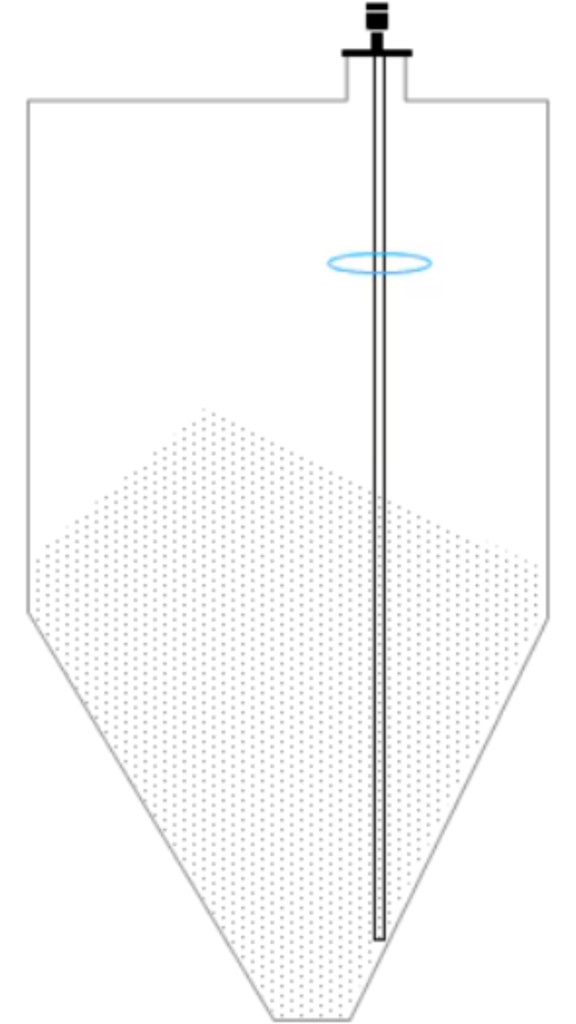

Microwave pulses propagate along a guide rope installed from the tank ceiling. The sensor measures the round-trip time of the reflected signal and converts it into the air distance to the measured object.

Non-contact level meters generally use two measurement principles: time-of-flight and phase difference detection.

A float attached to a stainless-steel tape tracks the liquid level, and the tape length is continuously measured to determine the empty distance. Types include spring-balance, sealed-pipe, and counterweight designs.

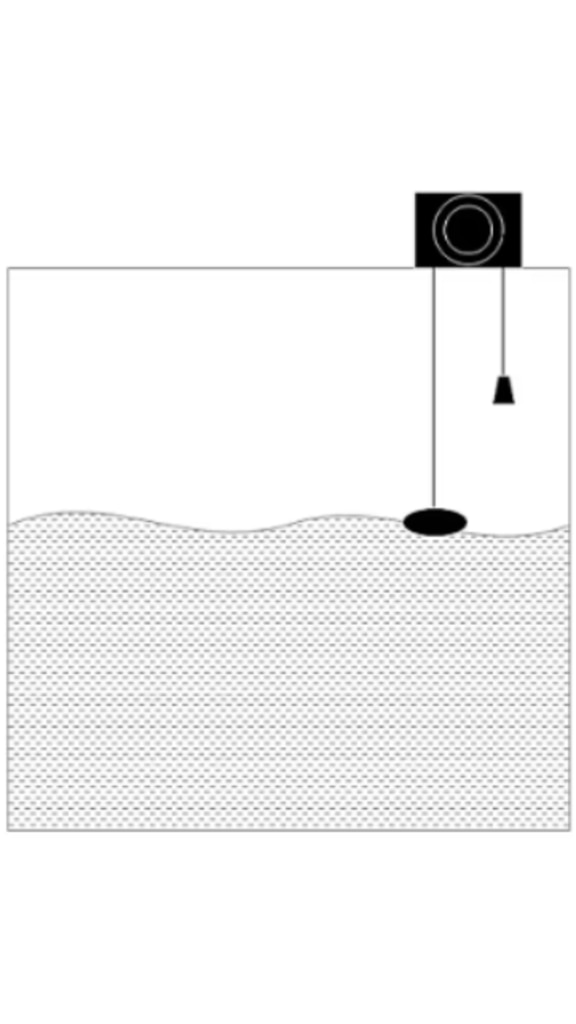

The displacer-type level transmitter uses a displacer with a density greater than that of the process liquid. Variations in liquid level cause proportional changes in buoyant force acting on the suspended displacer, which are mechanically transmitted and converted into a level signal.

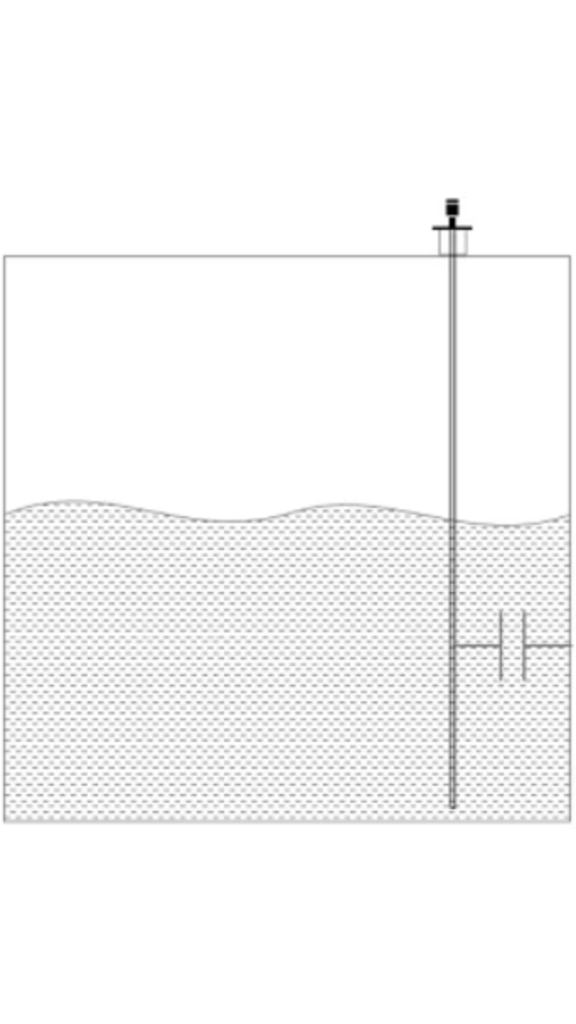

A capacitor is formed between a probe electrode suspended from the tank ceiling and the tank wall. When the measured material enters the space between the electrodes, the capacitance changes in proportion to the level. This change is measured and converted into a level measurement.

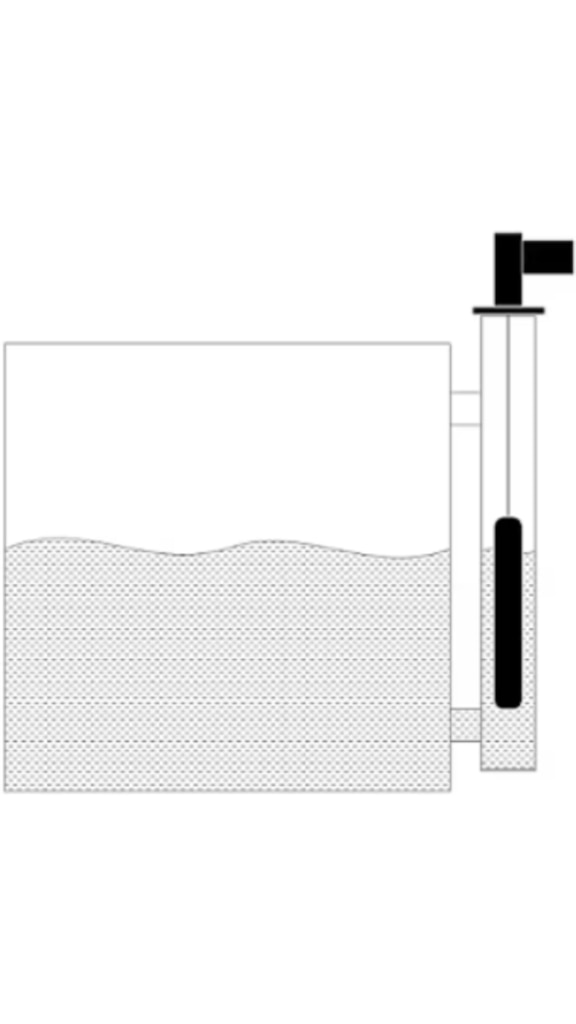

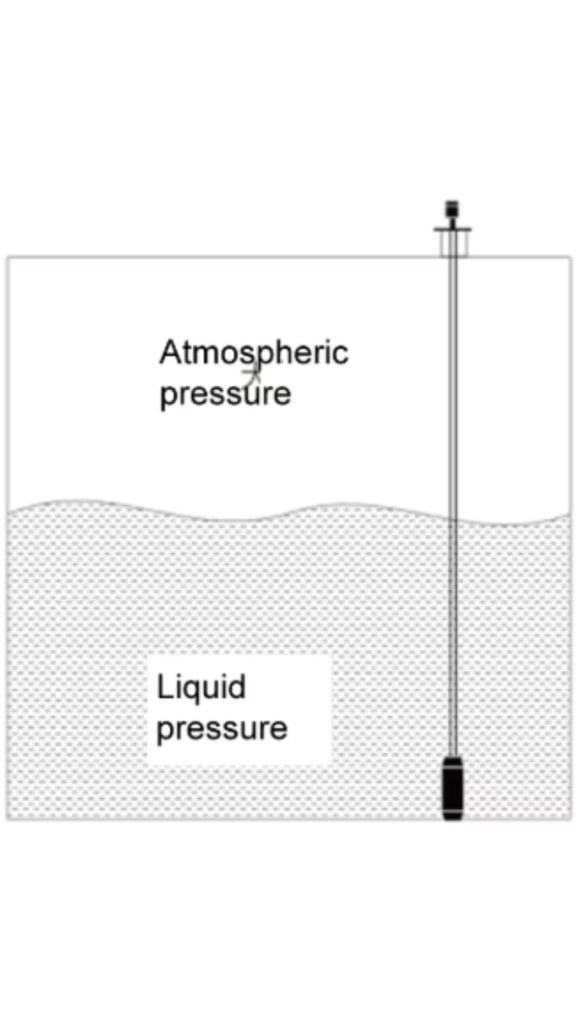

A diaphragm detects changes in liquid pressure caused by variations in liquid level and converts them into a level measurement. However, this method must be used under atmospheric pressure conditions inside the tank.

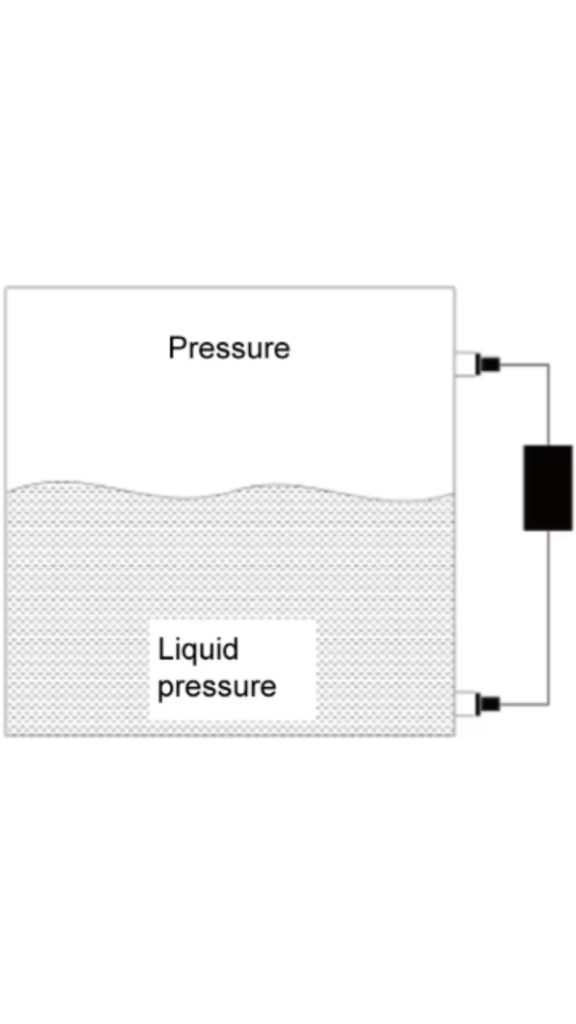

It consists of two diaphragms: one that measures liquid pressure and another that measures the internal tank pressure. The liquid level is calculated by subtracting the tank internal pressure from the measured liquid pressure.

Please feel free to ask us if you have any questions, inquiries or want our support.

Click here to download documents.

Click here for any questions.

Trivia, trends or information mainly for technologies.

Frequently Asked Questions.

WEBINAR archives available for free viewing.

© Matsushima Measure Tech Co., Ltd.